Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

Language

Featured Products

Ratings & Benchmarks

By Topic

Market Insights

Events

About S&P Global

Corporate Responsibility

Culture & Engagement

Featured Products

Ratings & Benchmarks

By Topic

Market Insights

Events

About S&P Global

Corporate Responsibility

Culture & Engagement

S&P Global Platts — 15 May, 2020

By Clement Choo

Highlights

As some national lockdowns begin to ease, Clement Choo assesses latest indicators of the health of the global auto industry, and the performance of a key input for the sector, steel coil.

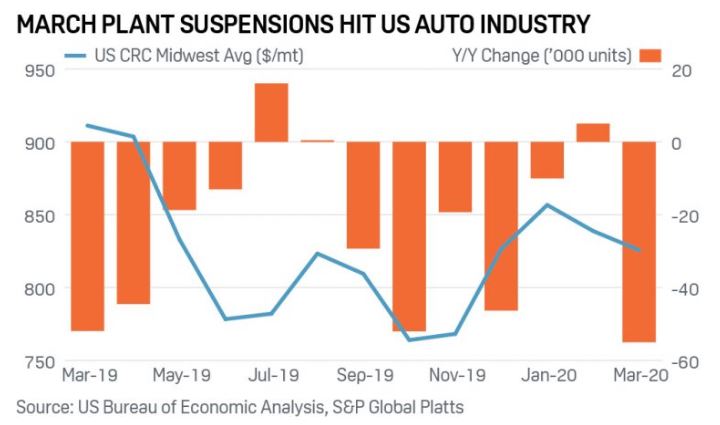

Vehicle markets saw their first quarter performance take a beating, with existing weak demand pummeled by the coronavirus pandemic as countries around the world reacted by going into lockdown.

GM suspended its 2020 profit outlook amid the uncertainty, after it added $16 billion to its cash reserves by tapping its credit lines.

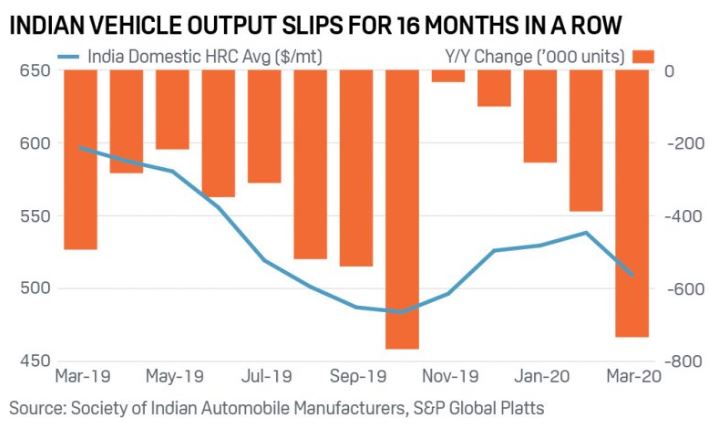

Initial April sales figures pointed to dismal showings, especially in India, where Maruti Suzuki India posted zero sales in the domestic market, with all of its plants shut due to the nationwide lockdown. Similarly, Bajaj Auto saw its April sales dive 91% year on year to 37,878 units. India’s lockdown, which began March 24, was initially due to end on April 14 but was extended twice to May 3 and then to May 17.

Amid the struggle against COVID-19, Japan’s Nissan Motor is expected to reduce its presence in Europe and widen it in China, its homeland and the US, in a plan due to be announced by the end of Q2.

Forward gear: Carmakers began to reopen production lines in May

Reverse gear: Vehicle sales dived in most markets, as did steel hot rolled coil (HRC) prices

Market forecasts are pointing to historic lows for vehicle sales in April but several market participants said that, as production resumes in May, demand could begin to show a modest recovery. Fiat-Chrysler cut its 2020 outlook for sales in the US market to 12.5 million units, down almost 27% from its earlier estimate of 17 million units.

Go deeper: Infographic – US steel, aluminum demand stalls on automakers’ shutdowns

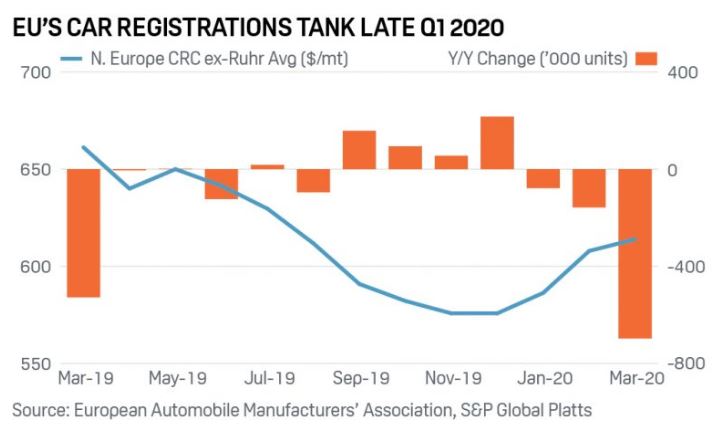

In line with an emerging global trend, EU manufacturing in April contracted to its lowest level since June 1997 due to the nationwide lockdowns. Germany saw its April PMI fall to its lowest in 133 months. European passenger car registrations tumbled 55% on the year in March to 567,308.

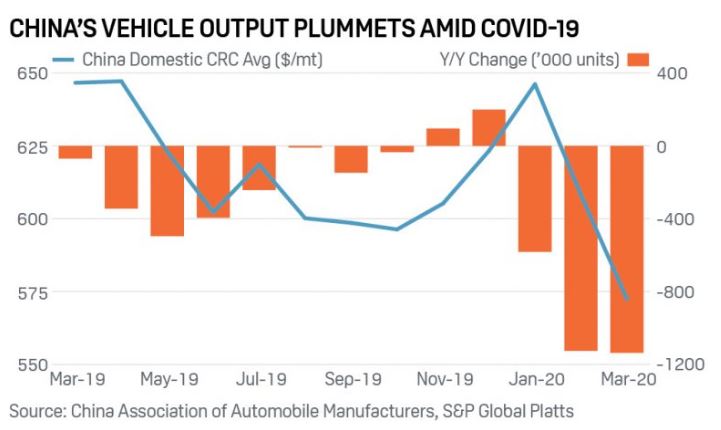

China’s recovery in manufacturing in March was short-lived as the manufacturing PMI published by the National Bureau of Statistics fell to 50.8 points in April from 55 in March, while the PMI published by Chinese media company Caixin retreated to 49.4 in April from 50.1 in March.

China’s car-making sector reached around 75% of normal operating levels in March, with output and sales up four-fold on February to 1.422 million and 1.43 million units respectively, according to China Association of Automobile Manufacturers data. However, output and sales were down 45% and 43% on March 2019, as CAAM warned the industry remained constrained by restrictions relating to the virus.

India’s manufacturing crumbled in April as its economic activity sank to its lowest in about 15 years, with the Nikkei manufacturing PMI contracting to 27.4 in April from 51.8 in March. Passenger car sales sank 52% in March against the year before. Overall, India saw its vehicle production for April 2019 to March 2020 (India’s fiscal year) fall 15% year on year to 26.4 million units.

Global demand could fall by 50% or more against 2020 amid market concerns of prolonged lockdowns or a resurgence of the coronavirus. Steel companies in Europe and the US have been slashing production due to the downturn in car making.

The downward trend will continue into Q2 as most global carmakers either shut or cut their operations in April, although several began to resume operations somewhat in May. The Indian government allowed some manufacturing to resume operations from April 20 subject to certain criteria, such as whether the location of the plant is outside a containment zone.

Nevertheless, the outlook is dim as annual projections are revised to reflect the negative market sentiment. For instance, the Federation of Thai Industries expects production to fall by 37% compared with 2019, to 1.33 million units, or even by 50% (to 1 million units) should the pandemic continue into June 2020. Past projections for 2020 were given at 2 million units in January and 1.9 million units in March.

The coming months could bring more downward revisions of key industry projections, as April-May data is expected to provide clearer indications.